Hot Strip Mill Work Rolls

Engineered roll solutions for high-temperature, high-pressure mill environments.

Overview

United Rolls designs and manufactures high-performance hot strip mill work rolls to meet the extreme demands of hot rolling environments. Our roll grades are engineered for superior wear, thermal fatigue resistance, and surface integrity, ensuring optimal performance and long service life under thermal and mechanical stress.

Roll Configurations & Grades

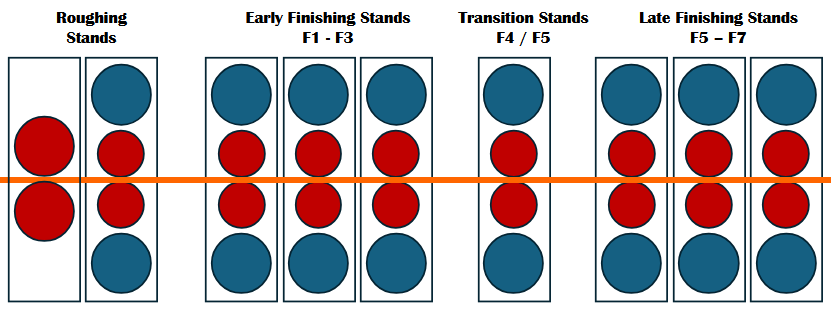

Roughing Stands

2-High Configuration

- Synergy 500: High chrome steel, excellent wear and peeling resistance, reduced fire cracking.

- UTEC: Enhanced ICDP, good wear resistance, cost-effective.

4-High Configuration

- Synergy 700: Modified high speed steel, excellent wear and peeling resistance, reduced fire cracking.

- Synergy 500: High chrome steel, strong wear resistance, excellent peeling resistance, reduced fire cracking.

- UTEC: Enhanced ICDP, good wear resistance.

Early Finishing Stands (F1 – F3)

- Synergy 100: High speed steel, excellent wear resistance, differential heat treatment for uniform hardness through shell, extended campaigns.

- HiCr: High chrome iron, strong wear resistance.

- UTEC: Enhanced ICDP, good wear resistance.

Transition Stands (F4 / F5)

- UR2-EC: Advanced niobium carbides for strong wear resistance, long campaign potential, reduced grind stock removal.

- UTEC: Enhanced ICDP, wear comparable to enhanced carbon grades, no risk of carbide segregation.

- Synergy 300: Graphitic high speed steel, strong wear properties, excellent surface retention.

- HiCr: High chrome iron, strong wear resistance, lower cost than high speed steel.

Late Finishing Stands (F5 – F7)

- UTEC: Enhanced ICDP, wear comparable to enhanced carbon grades, no risk of carbide segregation.

- UR2-EC: Advanced niobium carbides for strong wear resistance, longer campaign potential, reduced grind stock removal.

- ICDP: Good wear resistance, solid surface quality, reduced heat cracking.

Applications

Our hot strip mill rolls are used in steel mills around the world for processing carbon, stainless, and high-strength alloy steels. These rolls are ideal for:

- Finishing stands in hot strip mills

- High-speed, high-pressure rolling operations

- Applications where surface finish, wear resistance, and thermal shock durability are critical

Why Choose United Rolls?

Our commitment to quality begins at the design stage and carries through every phase of manufacturing. With decades of experience in iron roll production, United Rolls offers proven engineering, metallurgical insight, and a dedication to customer success. Whether you need premium performance or a budget-conscious solution, our roll grades are crafted to deliver results in the harshest operating conditions.

Request a Quote

Looking to improve your hot rolling operation’s performance or reduce downtime? Contact our team to request a quote or learn more about which work roll grade is right for your application.